হুয়াশি আইবিসি কেজ অটোমেটিক প্রোডাকশন মেশিন

হুয়াশি আইবিসি কেজ ফ্রেম অটোমেটিক ওয়েল্ডিং মেশিন একটি বিশেষায়িত উত্পাদন লাইন যা আইবিসি কেজ ফ্রেম উত্পাদন করার জন্য ডিজাইন করা হয়েছে। এই বিস্তৃত সিস্টেমে কেজ ফ্রেম স্বয়ংক্রিয় ওয়েল্ডিং,মেশি আনলোডিং যান্ত্রিক বাহু, জাল টার্নওভার কাঠামো, স্বয়ংক্রিয় ফ্রেম নমন মেশিন, লকিং মেশিন, গর্ত তৈরি এবং punching মেশিন, এবং স্বয়ংক্রিয় উত্পাদন লাইন চলন্ত যান্ত্রিক বাহু।সম্পূর্ণ লাইন শুধুমাত্র 2-3 অপারেটর প্রয়োজন যারা কেবল শুরুতে উপকরণ লোড এবং শেষ পণ্য আনলোড.

মূল সুবিধা

দক্ষ শক্তি খরচঃউন্নত ওয়েল্ডিং প্রযুক্তি এবং উপকরণগুলি উচ্চ-কার্যকারিতা শক্তি-ব্যবহারের অনুপাত নিশ্চিত করে, পরিবেশগত সচেতনতা প্রদর্শন করে এবং টেকসই উন্নয়নকে সমর্থন করে।

ব্যবহারকারী-বন্ধুত্বপূর্ণ ইন্টারফেসঃএকটি স্বজ্ঞাত ইন্টারফেস অপারেশনকে সহজ করে তোলে, প্রশিক্ষণের খরচ হ্রাস করে এবং অপারেশনাল দক্ষতা বৃদ্ধি করে।

টেকনিক্যাল স্পেসিফিকেশন

- ঢালাই দক্ষতাঃ 50 সেকেন্ড প্রতি টুকরা

- ঢালাই উত্সঃ 4 সেট এমএফ ডিসি পাওয়ার উত্স

- ফিডার প্ল্যাটফর্ম বিকল্পঃ একক স্তর বা ডাবল স্তর

- আনলোডিং সিস্টেম বিকল্পঃ ম্যানুয়াল আনলোডিং বা স্বয়ংক্রিয় যান্ত্রিক বাহু আনলোডিং

উৎপাদন ক্ষমতাঃ50 সেকেন্ড প্রতি টুকরা

প্রধান ওয়েল্ড ফ্রেম সিস্টেম

চারটি এমএফ ট্রান্সফরমার ওয়েল্ডিং ইলেকট্রোডের ছয়টি সেট নিয়ন্ত্রণ করে, প্রতিটি পয়েন্টের জন্য সর্বোত্তম ওয়েল্ডিং গুণমান নিশ্চিত করে।দ্বিপাক্ষিক পিয়ানো শৈলী ঢালাই কৌশল উল্লেখযোগ্যভাবে ঢালাই প্রক্রিয়া ত্বরান্বিত, এক মিনিটের মধ্যে প্রতিটি ধাতব গ্রিড জাল সম্পূর্ণ।

ডিজাইনটি সমতল ldালাই অবস্থানের গ্যারান্টি দেওয়ার জন্য উপরের এবং নীচের বায়ু সিলিন্ডার অন্তর্ভুক্ত করে।

ছয় মাথা আইবিসি ফ্রেম স্বয়ংক্রিয় ঢালাই মেশিন

ওয়েল্ডিং পাওয়ার সিস্টেমে উন্নত এমএফ ডিসি পাওয়ার উত্সের চারটি সেট রয়েছে, যা ছয়টি ভিন্ন স্থানে একযোগে ওয়েল্ডিং সক্ষম করে।দ্বৈত-স্তর ফিক্সচার ফিডার একটি ফিক্সচার উপর উপাদান লোডিং অনুমতি দিয়ে দক্ষতা বৃদ্ধি যখন ওয়েল্ডিং অন্য ঘটে.

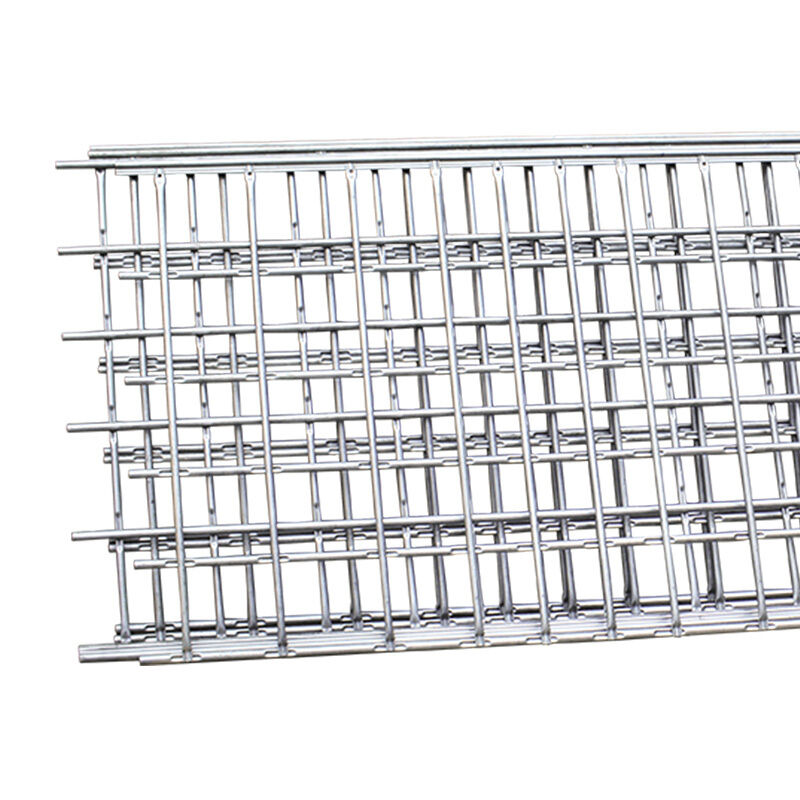

ফ্ল্যাট টিউব জাল এবং দৃঢ় ঢালাই গুণমান

ওয়েল্ডিং যন্ত্রটি টিউবগুলিকে একটি স্বতন্ত্র সমতল জাল কনফিগারেশনে রূপান্তরিত করে, শক্তিশালী, শক্ত ঝালগুলি নিশ্চিত করে। প্রতিটি সমতল জালের জন্য সম্পূর্ণ ওয়েল্ডিং প্রক্রিয়াটি প্রায় 60 সেকেন্ড সময় নেয়।

উল্লম্ব ডাবল স্টেশন আইবিসি ফ্রেম নমন মেশিন

এই বিস্তৃত প্রক্রিয়াকরণ মেশিনটি স্থিতিশীল অপারেশন এবং অসাধারণ দক্ষতার সাথে উচ্চ নির্ভুলতা বাঁকানোর গ্যারান্টি দেয়।

সমতল জালকে বর্গাকার আকারে বাঁকুন

নমন মেশিন দক্ষতার সাথে সমতল জালকে সুনির্দিষ্টভাবে বর্গাকার ফ্রেমে রূপান্তর করে, প্রায় ২০-২৫ সেকেন্ডে নমন প্রক্রিয়া সম্পন্ন করে।

বাঁকা মরীচি বৈশিষ্ট্য

- সিএনসি প্রক্রিয়াকৃত বাঁকানো মরীচি সঠিক বাঁকানো কোণ নিশ্চিত করে

- নমন মরীচি প্রতিটি ছাঁচ নমন পরিসীমা বৃদ্ধি করতে প্রায় 3 মিমি দ্বারা উপরে এবং নিচে সামঞ্জস্য করা যেতে পারে

- ১২০ ডিগ্রি ছাঁচের নকশা মসৃণ বাঁক কোণ তৈরি করে

বাঁকা ফ্রেম নির্মাণ

মেশিনের ফ্রেমের একটি শক্তিশালী আয়তক্ষেত্রাকার নকশা রয়েছে যা আরও পুরু ইস্পাত কলাম এবং দরজার আকারের কভার প্যানেলের সাথে রয়েছে, যা ব্যতিক্রমী দৃ firm়তা এবং স্থিতিশীলতা নিশ্চিত করে।

হাইড্রোলিক চাপ স্টেশন

বিশেষভাবে প্যালেট ট্যাঙ্কের জাল বাঁকানোর জন্য ডিজাইন করা, এই হাইড্রোলিক চালিত স্টেশনটি তাদের (1200±5 মিমি) * ((1000±5 মিমি) এর সুনির্দিষ্ট মাত্রা সহ আয়তক্ষেত্রাকার ফ্রেমে রূপ দেয়),সর্বোত্তম নমন কর্মক্ষমতা নিশ্চিত.

আইবিসি কেজ ফ্রেম লকিং মেশিন

এই সংহত ইউনিট সন্নিবেশের ক্ষেত্রে ব্যতিক্রমী নির্ভুলতা, শক্তিশালী লকিং শক্তি, এবং স্থিতিশীলতা এবং দক্ষতার একটি বিরামবিহীন মিশ্রণ প্রদান করে।

লকিং দক্ষতা এবং গুণমান

সামঞ্জস্যযোগ্য ক্লিনজিং আর্ম

- বৃহত্তর কাজের পরিসীমা জন্য বিভিন্ন আইবিসি ধাতু খাঁচা নকশা জন্য উপযুক্ত

- হাইড্রোলিক এবং বায়ুসংক্রান্ত নকশা মেশিনের দক্ষতা বৃদ্ধি করে

- পাইপ সাইডের স্বয়ংক্রিয় সংযোগের জন্য ডিজাইন করা

হাইড্রোলিক ক্লিনজিং মোল্ড

হাইড্রোলিক সিস্টেম পাইপগুলির জন্য টাইট ক্লিনজিং স্পট তৈরি করে, ধাতব খাঁচা ফাটল প্রতিরোধ করে।

হাইড্রোলিক চাপ স্টেশন

স্বয়ংক্রিয়ভাবে পাঠানোর ডিভাইস দিয়ে সজ্জিত যাতে ধাতব খাঁচা উৎপাদন সহজ এবং দক্ষ হয়।

আইবিসি কেজ ফ্রেম হোল তৈরি এবং পার্সিং মেশিন

এই মেশিনটি বেস ফ্রেমে নিরাপদভাবে সংযুক্ত করার জন্য ফ্রেমে গর্ত তৈরি করে।

গর্ত তৈরির দক্ষতা এবং গুণমান

হাইড্রোলিক শক্তি ব্যবহার করে, সম্পূর্ণ গর্ত তৈরি এবং punching প্রক্রিয়া প্রায় 25-30 সেকেন্ড সময় লাগে।

বৈশিষ্ট্যগুলির মধ্যে রয়েছেঃ

- প্রেসিং মোল্ড সহ প্রেসিং হেড

- হাইড্রোলিক স্টেশন

- প্যান্সিং হেডের অবস্থান প্যানেল

- বাম-ডান, সামনে-পিছনে নিয়মিত অবস্থান প্যানেল বৃহত্তর অবস্থান পরিসীমা জন্য

আইবিসি কেজ বেস ফ্রেম ওয়েল্ডিং মেশিন

এই অনুভূমিক কাঠামো মেশিনটি 7 টি ওয়েল্ডিং হেড সহ বেস ফ্রেমের ওয়েল্ডিং স্বয়ংক্রিয়ভাবে সম্পন্ন করে। অপারেটরদের কেবলমাত্র উপকরণগুলি লোড করতে হবে এবং ওয়েল্ড প্যালেটগুলি স্বয়ংক্রিয়ভাবে আনলোড করা হয়।

পণ্যের বৈশিষ্ট্য

- সম্পূর্ণ বেস ফ্রেম ওয়েল্ডিংয়ের জন্য 7 টি ওয়েল্ডিং হেড সহ অনুভূমিক কাঠামো

- সোয়েডেড প্যালেটের স্বয়ংক্রিয় আনলোডিং

- এমএফ ডিসি 250 কেভিএ পাওয়ার উত্সের 3 সেট

- খরচ কমানোর সাথে সাথে পণ্যের গুণমান এবং উৎপাদন হার বৃদ্ধি করে

- ম্যানুয়াল কাজ থেকে অস্থির ঢালাই মানের সমস্যা সমাধান করে

- উচ্চতর উৎপাদন হার এবং অটোমেশন স্তর

টেকনিক্যাল স্পেসিফিকেশন টেবিল

| পণ্যের নাম |

আইবিসি ফ্রেম উৎপাদন লাইন |

শৈলী |

একক সারি/ডাবল সারি |

| সর্বাধিক ওয়েল্ডিং প্রস্থ |

১২০০ মিমি |

সর্বাধিক ওয়েল্ডিং দৈর্ঘ্য |

৪২৫০ মিমি |

| ব্র্যান্ড |

হাওয়াশি |

রঙ |

নীল / হলুদ / কাস্টম |

| সজ্জিত শক্তি |

৩৫০ কেভিএ/৪০০ কেভিএ |

পণ্যের স্থান |

চেজিয়াং প্রদেশ, চীন |

| ভোল্টেজ |

৩পি ৩৮০ ভোল্ট |

উপাদান |

গ্যালভানাইজড পাইপ |

| পাইপের বেধ |

১-২ মিমি |

ডিউটি চক্র |

২০% |

| পাইপের ব্যাসার্ধ |

১৪-২০ মিমি |

ঘনত্ব |

50HZ/60HZ |

| পাইপ লোডিং পদ্ধতি |

ম্যানুয়াল/2 শ্রম |

ক্যাবলের আকার |

≥70mm3 |

| কর্মক্ষমতা |

৩৫০-৪৫০ ((৪৮০-৫৫০) পিসি/৮ ঘন্টা |

বায়ু পাইপের আকার |

জি১ |

| শ্রম চাহিদা |

২-৩ টা কাজ |

পানির পাইপের আকার |

G1 1/4 |

উৎপাদন লাইন বিন্যাস বৈশিষ্ট্য

- ট্যাঙ্ক পাঠানোর সিস্টেমঃ পৃথক ফুঁ মেশিন এবং খাঁচা কর্মশালা সঙ্গে কারখানা জন্য উপযুক্ত

- মানব হস্তক্ষেপ ছাড়াই কনভেয়র দ্বারা কেজ কর্মশালায় পরিবহন পরীক্ষার ট্যাঙ্ক

- আইবিসি বাঁকা, ক্লিঙ্কিং এবং পঞ্চড খাঁচা স্থাপন এলাকা

- ওয়েল্ডেড প্যালেট স্টোরেজ এলাকা

- অটো প্যালেট একত্রিত পথ

- প্যালেট ওয়েল্ডিং স্টেশন

- ঘূর্ণনশীল খাঁচা এবং প্যালেট একত্রিত এলাকা

- নিরাপদ পথের নকশা

- স্বয়ংক্রিয় খাওয়ানোর সাথে প্যালেট প্লেট স্টকিং এলাকা

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে!

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে! অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!

অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!  আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে!

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে! অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!

অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!